PVC high-efficiency flame retardant

Download:

Introduction

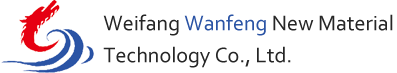

The light-colored PVC-specific magnesium hydroxide developed by our company has achieved a significant leap in thermal stability. At the same processing temperature, its thermal decomposition time is more than 30 minutes longer than that of traditional magnesium hydroxide. After undergoing long-term high-temperature plasticization, it can still stably maintain the integrity of the PVC molecular chain, fundamentally avoiding color changes in the products due to heat exposure.

In the production field of light-colored PVC products, thermal stability, color retention, and smoke control have always been the core challenges of the industry. Although traditional magnesium hydroxide can meet basic flame retardancy and smoke suppression requirements, it often causes the products to turn yellow and char due to performance degradation under high temperatures. Therefore, our special magnesium hydroxide not only has the performance of efficient flame retardancy, increasing the oxygen index and reducing the smoke density, but also completely avoids yellowing and charring.